Glasgow Lab Pioneers 3D Printing for Space: NextSpace Testrig Tackles Orbital Debris Risk

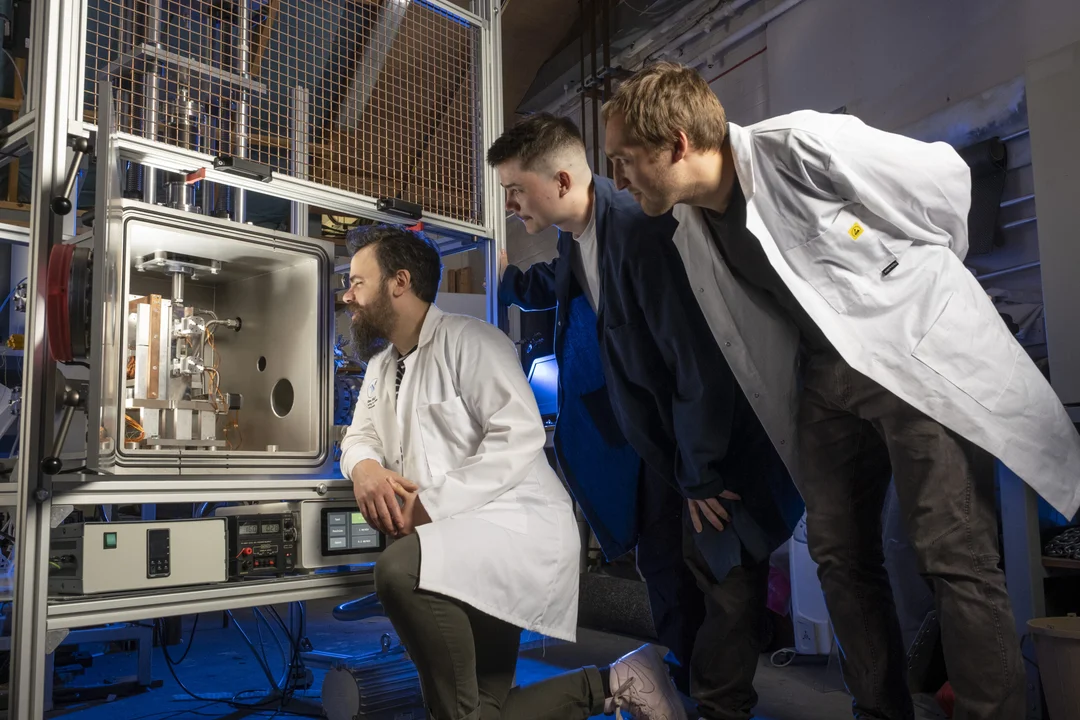

The University of Glasgow has unveiled the NextSpace Testrig, the world's first dedicated testing facility designed to ensure the structural integrity of materials 3D printed in space. This groundbreaking initiative addresses a critical challenge in the burgeoning field of space manufacturing: mitigating the dangers of orbital debris caused by potential structural failures of in-space printed components.

With space agencies and private companies increasingly looking to build infrastructure directly in orbit, the ability to rigorously test and validate 3D-printed materials under space-like conditions is paramount. Launching fully assembled equipment into space is costly and limited by rocket size. Space manufacturing, using specialized 3D printers to build complex components in orbit, offers substantial savings and logistical advantages.

The NextSpace Testrig, supported by £253,000 from the UK Space Agency's Enabling Technology Programme, recreates the harsh environment of space within a custom-built vacuum chamber. Temperatures can swing from -150°C to +250°C, replicating the thermal extremes that orbiting materials endure. The facility’s unique magazine system allows automated testing of multiple samples, subjecting them to forces equivalent to 2,000 kg while monitoring for signs of failure. This allows researchers to study how 3D-printed polymers, ceramics, and metals perform under intense physical stress.

Dr. Gilles Bailet, who leads the project in collaboration with The Manufacturing Technology Centre, emphasizes the significance of this research: "3D printing is a very promising technology for allowing us to build very complex structures directly in orbit instead of taking them into space on rockets. It could enable us to create a wide variety of devices, from lightweight communications antennas to solar reflectors to structural parts of spacecraft or even human habitats for missions to the Moon and beyond."

However, the potential benefits come with the risk of space junk. Even minor imperfections in 3D-printed parts, such as air bubbles or poorly fused layers, can cause catastrophic failures under orbital conditions. Fragments from disintegrated components can travel at rifle-bullet speeds, posing a serious threat to satellites and spacecraft. The NextSpace Testrig aims to mitigate this risk by providing reliable data on the behavior of 3D-printed materials in space-like environments, informing safety standards for in-orbit construction.

Highlighting the global importance, Dr. Bailet stated, “The NextSpace TestRig is open to academic colleagues, researchers and commercial clients from around the world to help them ensure that any materials they plan to 3D print in space will work safely.” He anticipates that the data will aid regulatory authorities in setting safety standards for in-space manufacturing.

Glasgow is already a prominent hub for satellite manufacturing. This new technology solidifies the city's position as a global leader in space technology and boosts the UK's space sector's competitiveness. Dr. Bailet has also developed a prototype 3D printer for orbital use, tested on parabolic research flights, paving the way for future missions where spacecraft are assembled and maintained in orbit, reducing reliance on costly Earth-based launches.

The NextSpace Testrig is now accessible to academic researchers and commercial partners worldwide, offering unique capabilities. This initiative supports scientific discovery and ensures the safety and sustainability of our ambitions in orbit.

What implications does this breakthrough have for the future of space exploration and manufacturing? Share your thoughts and opinions in the comments below!